VARIOPRINT Pad printing

Technology, application and different models according to your needs

Pad printing is an indirect printing method (gravure printing principle), which has developed into the most important method for printing on plastic items, and particularly for printing on technical parts.

The printing plate holds the deeper printing image to be printed in its surface. The scraper presses the paint into the deeper printing image and cleanly scrapes off the excess paint. At the same time as the scraping process, a pad made of silicon rubber moves from the printed goods to the plate. The pad is lower over the printing block and thereby takes on the printing image. Pad printing is therefore an indirect printing method. Then, the pad lifts and moves to the printing material. There, the pad lowers and fits itself to the plate.

The advantage of this print transfer is the malleability of the pad, through which printing of curved surfaces (convex, concave or irregular) is enabled. Due to its elasticity, the pad takes on the shape of the item to be printed on and can therefore ideally transfer the motif to the printing material. The printing image is transferred to the print item. The transfer of paint onto the printing material is nearly 100%, due to the silicon oil base in the pad.

Due to its adaptability when printing, pad printing can be used on any conceivable items. Examples of fields of application are the printing of syringes, toys, CDs, crockery, screw caps, lighters and tool handles. Particularly also in the automotive sector, many parts are decorated using pad printing. Each of us has already touched an indicator or windscreen wiper lever.

In the advertising media industry and with model trains, this printing technique is used particularly frequently, as a great deal of advertising merchandise and railway models do not have even surfaces.

The mechanical structure of the painting system is differentiated into three basic types:

Open painting system

From approx. 1971, the paint is in an open paint reservoir, is painted over the printing block by the paint spatula and the excess paint is scraped off by the scraper. An advantage of this system is given with large printing surfaces. With small printing surfaces, this painting system is regarded as being obsolete.

Closed painting system

From approx. 1983, paint is in a hermetically sealed paint pot, which simultaneously contains the scraping element and scrapes off the excess paint, through a surrounding scraper ring made of hard metal or ceramic. The scraper ring is simultaneously the sealing element. In order that paint does not leak, the pot is press against the printing block, with some machines, this takes place with magnets, with others, using an adjustable spring preload or a pneumatic press.

Rotation pad printing

From approx. 1981, for printing on round parts or for continuous printing. The pad and the printing blocks are shaped as rolls and therefore allow a continuous movement process. The paint is in an open paint reservoir. Application, e.g. in systems for printing bottle caps or plastic profiles.

With some pad printing machines, the movements take place pneumatically, while with others, primarily fast machines, they take place electromechanically using curved disks. The latest generation of pad printing machines is driven by electromechanical linear axle, which ensures a programmable process flow. Through automatic parts recognition, diverse print images can be specified, without the printing block needing to the changed.

High-quality machines usually have automatic equipment for cleaning the pad (pad cleaning, residual paint collection). Machines to be integrated in automation are purposefully equipped with SPS controls and matching interfaces.

1-color pad printing machines

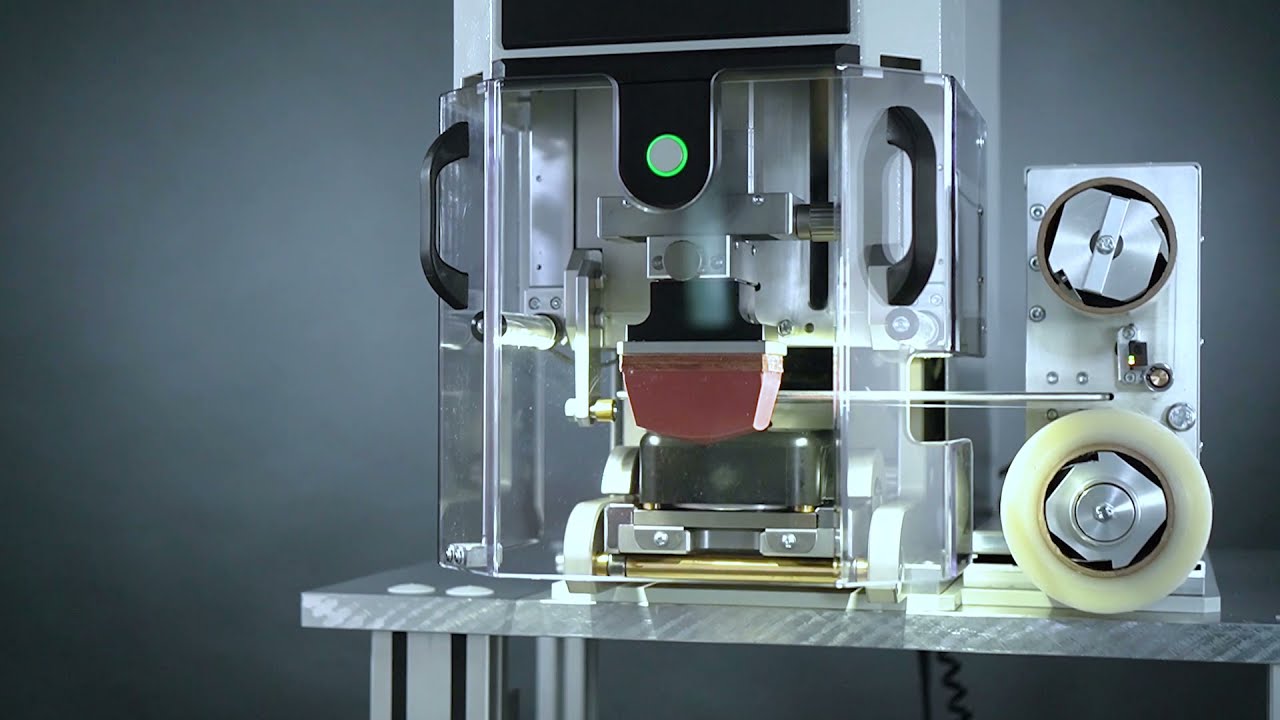

Pad printing machine VARIOPRINT- tampo 611s / 711s

Single color pad printing machine with

- Electrical drive

- Multiple image technology

- VARIOPRINT Patent No. 4412599

Special features:

- Multiple image technology - without printing block change

Several print images are arranged on one printing pad. The required print image is selected and transferred through automatic positioning of the printing block below the pad. This multiple image technology allows the identification of variants in a rapid change. This way, one printing machine takes place of several tasks, e.g. on the front and back of the print item. - Paint system – closed and with ceramic ring or hard metal ring

Close painting system with replaceable ceramic ring. Through the material combination of steel/plastic printing block and ceramic scraper, the service life of the components is optimised. Dismantling of the paint system by simply releasing the holding lever. - Saving energy in pad printing

High energy efficiency due to optimized, electric drive

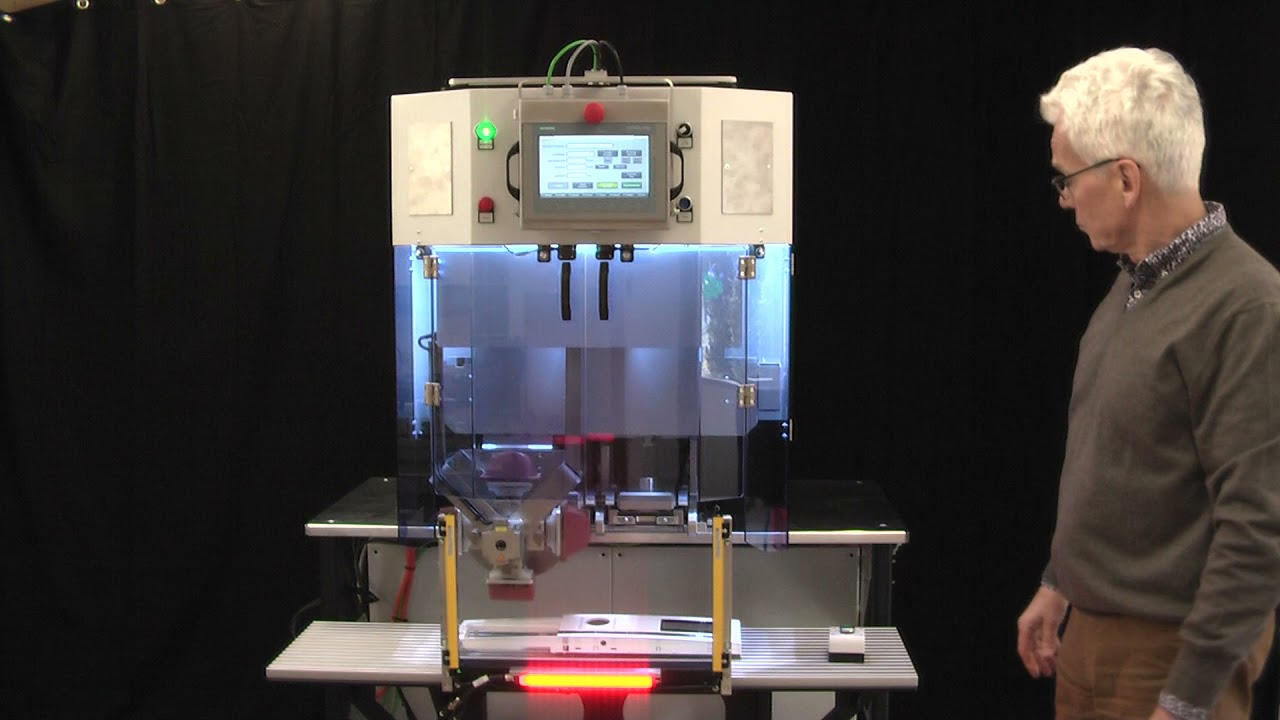

Pad printing machine VARIOPRINT- tampo 911cs / 1011cs / S

Single color pad printing machine with

- Printing image change

- Printing block change

- Safe machine type design S

- VARIOPRINT Patent No. 4412599

Special features:

- Printing image change—without printing block change

(multiple image technology) Several printing images are arranged on one printing block. The required print image is selected and transferred through positioning of the printing block below the pad. - Printing pad change – without painting system removal

For changing the printing block, the push of a button is sufficient for automatically releasing the printing block. A parking plate protects the painting system.

- Work station design – optimised for your printing task

Two doors for optimum protection and accessibility. Swivelling operating field.

Ink systems

- The optimum ink system for every application

- VARIOPRINT ink systems with ceramic and carbide doctor rings

- Ink cup also rotatable

- Magnetic sealing inside and outside

2 color pad printing machine

Pad printing machine VARIOPRINT- tampo 1021cS

Two-colour machines with electrical CNC drive

- Positioning of various single-print images

- Automatic print pad change

- Multiple image technology

Special features:

- Multiple image technology - without printing block change

Several print images are arranged on one printing pad. The required print image is selected and transferred through positioning of the printing block below the pad. - Printing image positioning - with CNC control

Printing image positioning using CNC control in X and Y direction. Mechanical gauge pin correction of the printing block axles not necessary.

- Printing pad change with revolver pad holder

Four pas are arranged on a revolving drive (revolver). This way, four individual images can be transferred in one printing process. Cleaning of pads without time delay.

Applications:

- Switching device printing with automatic changing of type descriptions

- Printing on elongated printing parts with individual printing images

- Printing changing production or control data